Introduce the safety start-up precautions of electrolyzer stack

Release time:

Dec 19,2021

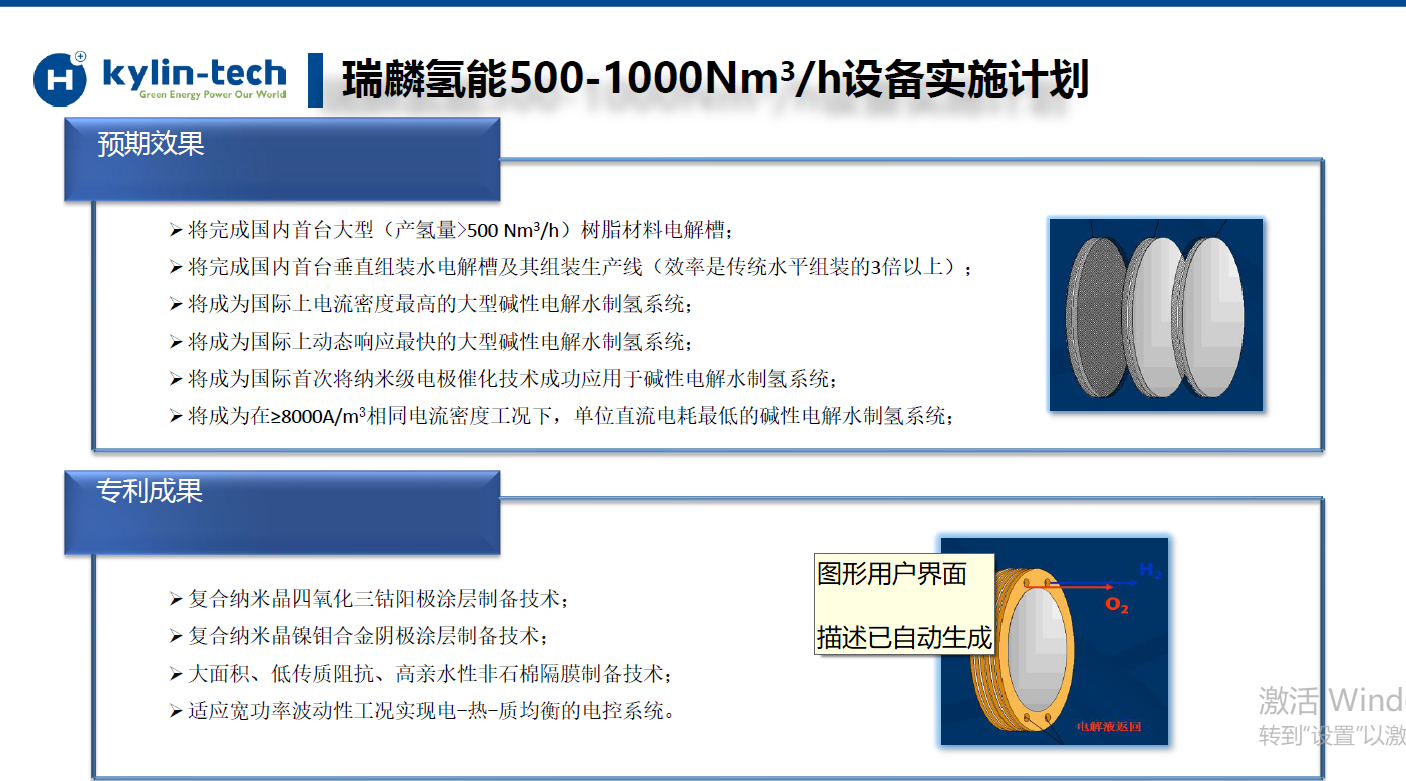

The electrodes in the electrolyzer stack are compact in vertical installation, the conductive plates are easy to connect, and the bubble effect is reduced. The working surface area of the electrode is reduced due to bubbles often attached to the surface of the electrode where gas is evolved. In addition, the solution near the electrode is also filled with bubbles, increasing the resistance of the solution.

This phenomenon is called the "bubble effect". However, near the surface of the vertical electrode, the characteristics of high aeration, low density and fast rising speed in the solution can be used to form a natural circulation of the electrolyte, so that the bubbles can be accelerated to leave the surface of the electrode and reduce the bubble effect. When the vertical electrode is used as a gas electrode, the shape of the electrode is more than a mesh, which not only increases the working surface area, but also facilitates the escape of bubbles.

The electrolyzer stack material may be steel, cement, ceramic, etc. Steel alkali resistance, is the most widely used. For highly corrosive electrolytes, the steel tank is lined with lead, synthetic resin or rubber. At present, the electrolyzer stack is developing in the direction of large capacity and low energy consumption. The bipolar electrolyzer stack is suitable for large-scale production and has been used in the electrolytic water and chlor-alkali industries.

Water electrolysis hydrogen production electrolyzers mostly use iron as the cathode surface and nickel as the anode surface in series electrolyzers (shaped like a filter press) to electrolyze aqueous solutions of caustic potash or caustic soda. Anode out of oxygen, cathode out of hydrogen. This method has high cost, but the product purity is high, and can directly produce hydrogen with a purity of more than 99.7%.

Key words:

Related News