Kylin Technology's high-performance hydrogen production system with a daily output of 100kg of hydrogen is shipped

Release time:

Jun 02,2022

On June 1, Shanghai, which had been under lockdown for two months, finally reopened, and various social and production activities gradually resumed!

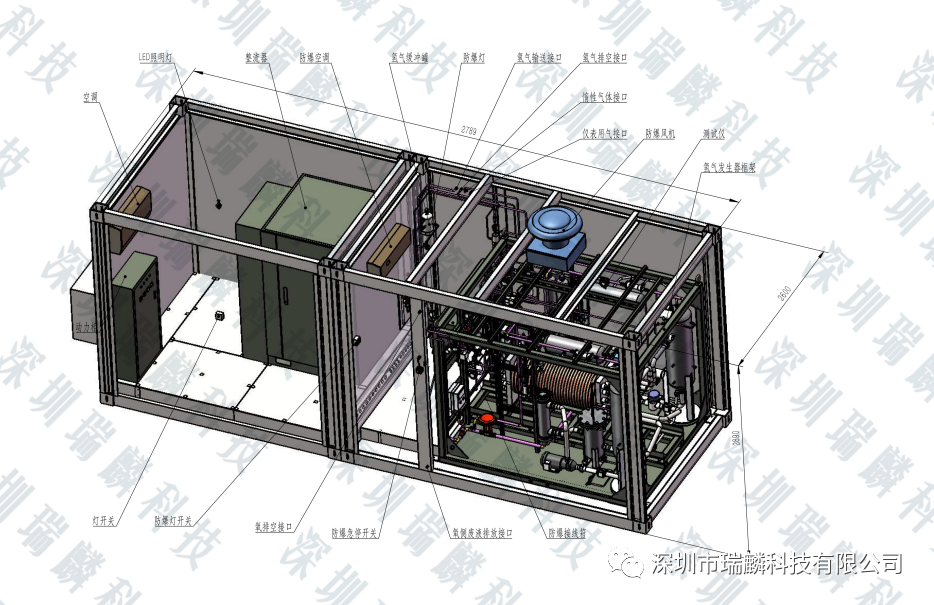

The electrolysis equipment produced by Shenzhen Kylin Technology Co., Ltd., a representative enterprise in alkaline water electrolysis technology, is scheduled to be shipped smoothly to a well-known hydrogen refueling station construction company in Shanghai. The daily production capacity of this equipment is 100 kilograms of hydrogen. The integrated skid-mounted hydrogen production equipment provides on-site hydrogen production and on-site refueling for integrated energy stations combining oil, gas, and electricity, effectively reducing on-site hydrogen storage. It is one of the typical application scenarios for future distributed skid-mounted hydrogen production. Currently, many places are also exploring hydrogen production policies and demonstration projects outside chemical industrial parks, indicating that the demand for distributed integrated skid-mounted hydrogen production will become even stronger in the future, with more flexible application scenarios.

Sketch of Integrated Skid-Mounted Assembly

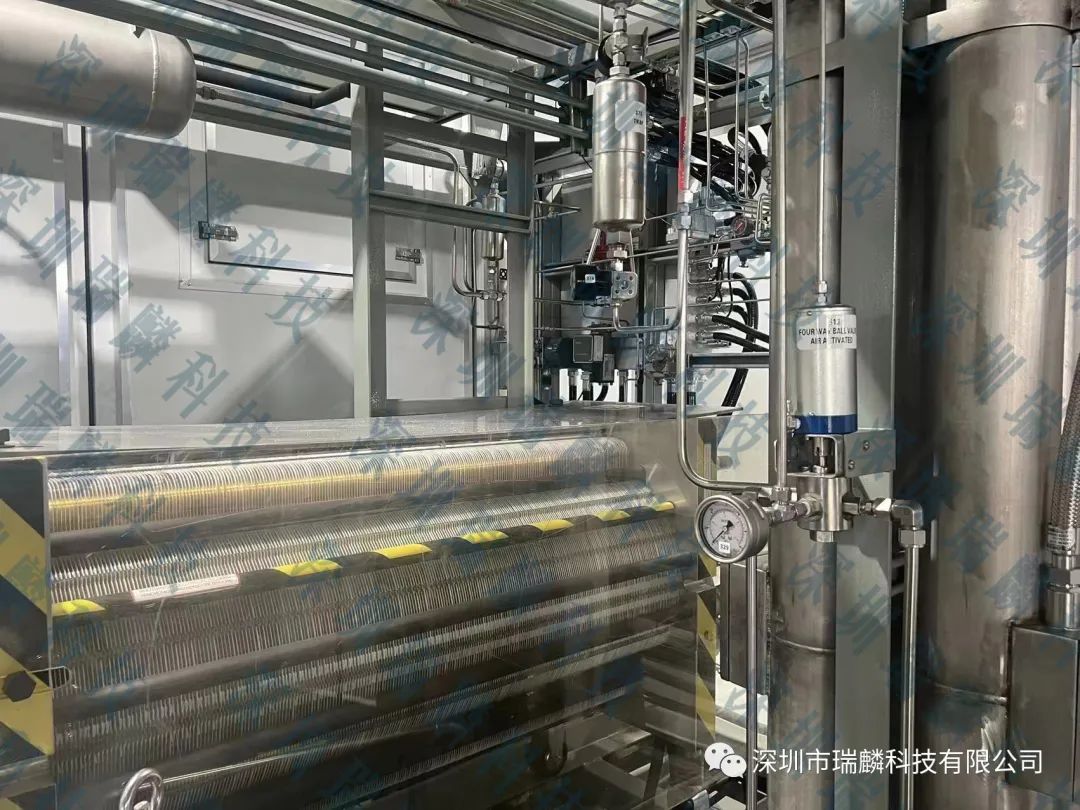

This hydrogen production equipment has high dynamic response and wide load capacity (achieving 10%~110% load change within 20 seconds), with performance comparable to PEM, and can be fully off-grid coupled with renewable energy power generation.

"Focus on product performance and serve customers with sincerity." Currently, the company has an annual production capacity of 300MW, covering a full range of products from 2 to 1000 standard cubic meters. It can meet the application needs of traditional industries such as semiconductors and new materials, as well as the emerging scenario of green hydrogen production using renewable energy power generation. The company's products are distinguished from other domestic alkaline technology enterprises, with performance that traditional alkaline equipment lacks:

A. High current density: Current density can reach over 10,000A/m2.

B. Small size: It is one-fifth of the size of traditional alkaline equipment with the same gas production capacity.

C. High dynamic response: Load change rate of over 5% per second, achieving 10%~110% load response within 20 seconds.

D. Wide operating range: Stable operation at a minimum load of 5%, producing high-purity hydrogen with a purity of up to 99.9998%.

Physical drawing of internal electrolytic cell

Shenzhen Kylin Technology has been focused on the research, development, and production of new-generation electrolysis water hydrogen production technology for 15 years. Driven by technology to reduce the cost of green hydrogen, the company will continue to expand "green electricity + green hydrogen" scenarios, promote technological innovation, and continuously create value for customers!

Key words:

Related News