Comparison of Proton Exchange Membrane Hydrolysis Hydrogen Production and Alkaline Tank Hydrolysis Hydrogen Production Machine

Release time:

Oct 28,2021

According to the different nature of the electrolyte, electrolytic water hydrogen production technology is mainly divided into four types:

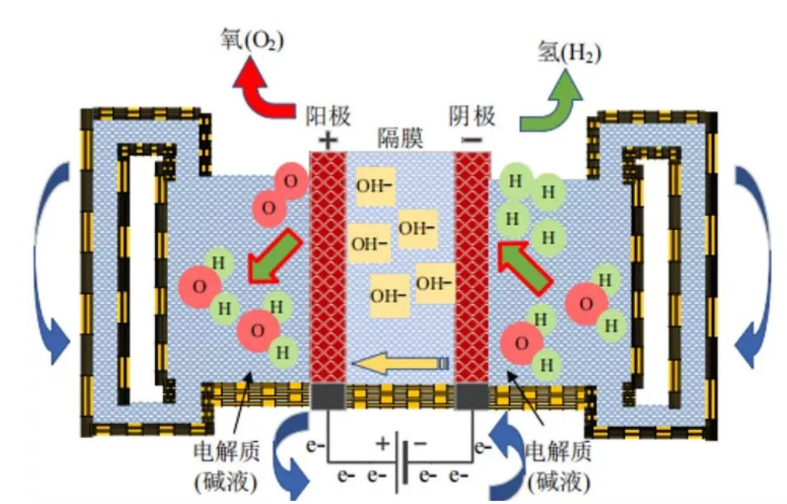

1.AWE: Hydrogen Production from Alkaline Water Electrolysis

Schematic diagram of AWE water electrolysis hydrogen production principle

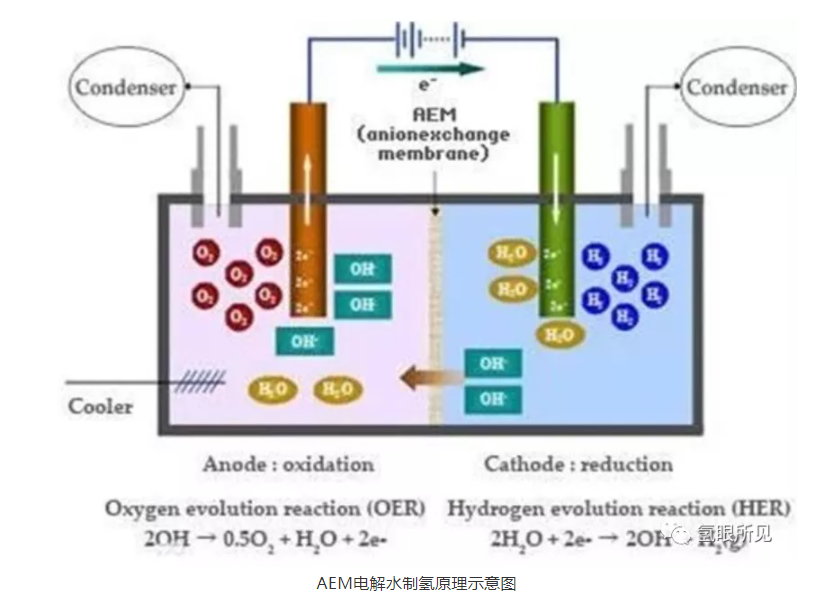

2.AEM: Anion Exchange Membrane Water Electrolysis for Hydrogen Production

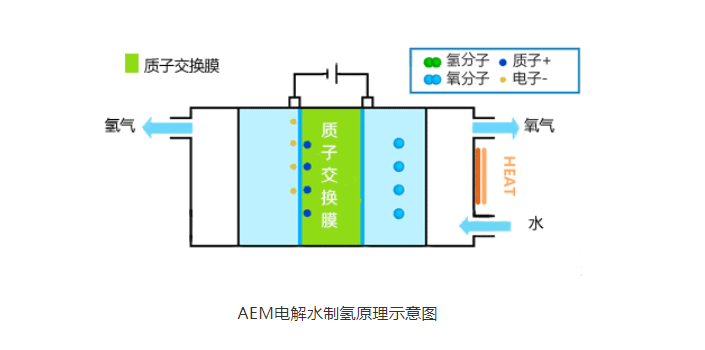

3.PEM: proton exchange membrane electrolysis

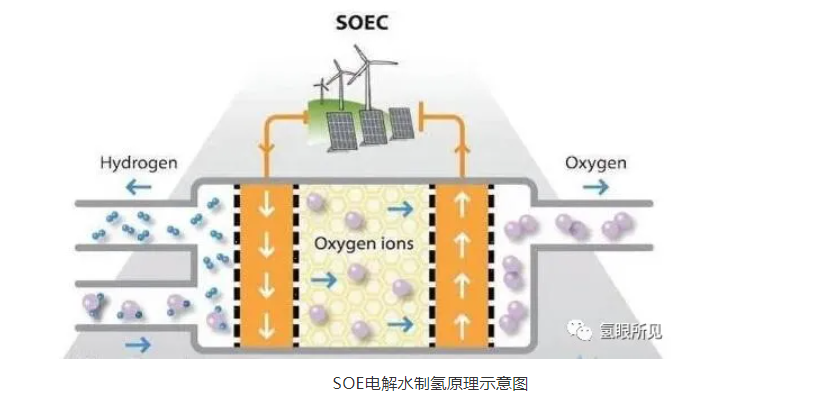

4.SOE: High Temperature Solid Oxide Water Electrolysis for Hydrogen Production

Since AEM and SOE are currently only at the laboratory stage without any commercial demonstration applications, we will briefly discuss the advantages and disadvantages of AWE and PEM hydrogen production methods. Recently, the development momentum of PEM hydrogen generators in the domestic market has gradually strengthened, and many merchants have vigorously promoted PEM hydrogen generators, making many users mistakenly believe that PEM water electrolysis technology is already fully mature. Given this situation, we will briefly clarify the current status to avoid users' blindness in choosing hydrogen generators. Below, we will analyze and compare alkaline water electrolysis hydrogen production and proton exchange membrane (PEM) pure water hydrogen production from five aspects.

- Alkaline hydrogen generators are cheaper (current approximate unit price of 2 to 3 million yuan per MW), while PEM hydrogen generators cost approximately 10 million yuan per MW (imported equipment costs even more, reaching over 15 million yuan per MW based on known contracts). Therefore, the cost of current PEM-type hydrogen production equipment is almost four times or even more than that of AWE.

Alkaline electrolysis technology has been highly mature at this stage. Early alkaline electrolyzers commonly used asbestos membranes as separators. However, with the discovery of asbestos's carcinogenicity, advanced countries such as Europe and the United States have phased out asbestos membranes and begun using more environmentally friendly ion-exchange membranes or inorganic-organic composite membranes. These membranes have increased current density and higher efficiency. The tank structure of alkaline electrolyzers is simple, easy to operate, and the raw materials used in production are neither monopolized nor expensive, making the overall cost relatively low and more acceptable to hydrogen generator users.

The core of PEM water electrolysis technology is the proton exchange membrane, which should possess excellent chemical and thermodynamic stability as well as good proton conductivity. At the same time, the membrane surface should have good compatibility with the catalyst to effectively prevent gas diffusion and separate hydrogen and oxygen from mixing. Currently, the most widely used membrane is Nafion from XX Company. Although Nafion membranes have many advantages, their high price increases the cost of PEM water electrolysis technology. In PEM electrode structures, due to the acidic nature of the electrolyte, electrode materials must be corrosion-resistant and stable. Currently, the metals used as catalysts are almost entirely limited to precious metals and their alloys, with platinum-based metals and their alloys being the most widely used hydrogen evolution catalysts. Although researchers have significantly reduced costs by coating platinum metal catalyst thin layers on porous electrodes using coating methods to increase the active surface area of the catalyst and reduce platinum metal usage, the high cost of PEM membranes and platinum metal catalysts still results in PEM hydrogen generators being significantly more expensive than alkaline electrolysis hydrogen generators. Currently, on a par with gas production, the price of a PEM hydrogen generator is approximately four times or more than that of an alkaline electrolysis hydrogen generator.

- Alkaline electrolysis hydrogen generators (AWE) have mature technology, while PEM water electrolysis is still in the small-scale demonstration and testing phase.

The technology of alkaline electrolysis hydrogen generators is already highly mature, which is a recognized fact in the current water electrolysis hydrogen production industry. For decades, alkaline hydrogen generators have been widely used in various industries, and there are numerous practical cases available for reference regarding continuous stable operation, maintenance, and lifespan. PEM hydrogen generators have only recently had minor commercial applications as manufacturers continue to reduce manufacturing costs, but they have not been widely adopted due to the high cost of materials and technological limitations. Currently, commercially available PEM water electrolysis hydrogen generators produce approximately 1-10 m³/h of gas (using multiple parallel units), with a pressure of 0-3 MPa. Single electrolysis cells typically produce 2 Nm³/h. Whether in terms of gas production or hydrogen delivery pressure, PEM hydrogen generators cannot compare with alkaline electrolysis hydrogen generators. Larger-scale (MW-level) commercial PEM water electrolysis hydrogen generators are currently only being demonstrated by a few research institutions and companies.

In practical applications, only a few companies, such as Hydrogen XX from Canada, have projects in Germany and Denmark with single PEM electrolysis cells reaching 200 Nm³/h (corresponding to 1 MW of power). You can keep an eye on their current usage status. There are also two MW-level PEM water electrolysis hydrogen production projects in China that will be put into trial operation this year. You can follow their current status, continuous operation, and maintenance conditions, as this information is relatively transparent and accessible.

- The service life of alkaline electrolysis hydrogen generators is 8-15 years, while PEM hydrogen generators last more than 2 years. Due to the immaturity of the technology and manufacturing process, lack of practical engineering experience, and significant current fluctuations during operation, the proton exchange membrane (PEM) water electrolysis hydrogen generator tends to produce more impurities during the electrochemical reaction process in the electrolyzer. The presence of these impurities reduces the activity of precious metal catalysts, which in turn decreases the electrolysis efficiency and shortens the lifespan of the electrolyzer. Currently, the lifespan of PEM electrolyzers is generally over 2 years (even without being verified by actual engineering cases), while the lifespan of the relatively mature alkaline electrolyzers ranges from 8 to 15 years, or even longer.

4. PEM Demands Stricter Water Quality

Both PEM electrolyzers and alkaline electrolyzers require deionized and purified tap water for use. Currently, PEM hydrogen generators on the market require a conductivity of 1us/cm (corresponding to a resistivity of 1 mω.cm) for pure water, while alkaline hydrogen generators typically require a conductivity of 10us/cm (corresponding to a resistivity of 0.1 mω.cm). This shows that PEM water electrolysis hydrogen generators have slightly stricter requirements for water quality.

5. The theoretical power consumption per standard cubic meter of hydrogen for both methods is essentially the same, ranging from 4.5 to 6.5 kWh/scm in actual conditions.

However, due to PEM's higher current density, PEM-type equipment theoretically has a slight advantage in terms of equipment volume compared to alkaline hydrogen generators.

The most significant difference in volume between the two types of equipment lies in the electrolyzer section. Comparing PEM water electrolysis at 2A/cm² and alkaline water electrolysis at 400mA/cm², there is a noticeable difference. Currently, some enterprises have also increased the current density of alkaline electrolyzers to a higher level, effectively reducing this volume difference.

Conclusion:

For PEM water electrolysis hydrogen generation equipment to gain an absolute advantage in the future hydrogen generation equipment market, it must make breakthroughs in terms of cost, lifespan, high power, and accumulation of practical engineering experience. Otherwise, alkaline electrolyzers will remain dominant for a considerable period of time.

Key words:

Related News