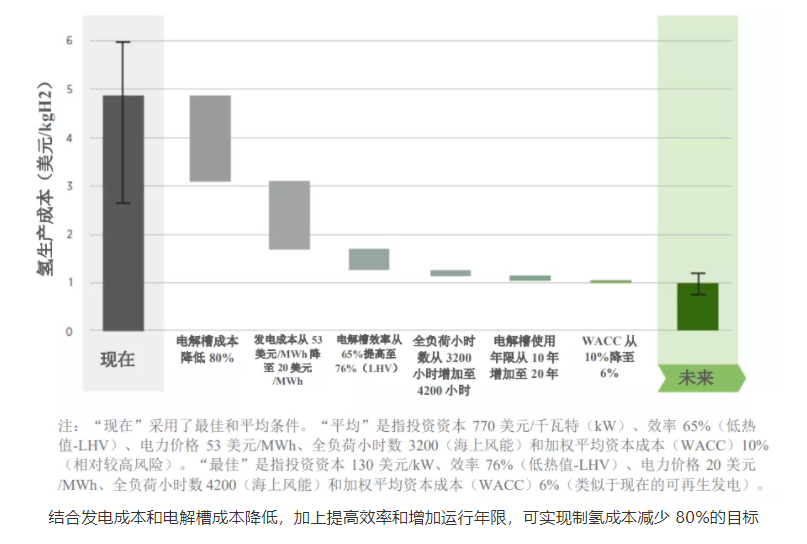

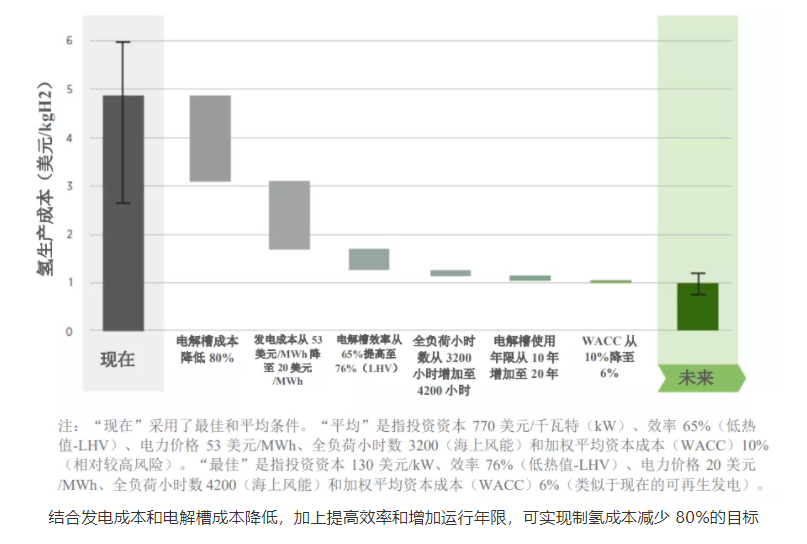

1. factors that affect the cost of green hydrogen:

1. Electricity cost

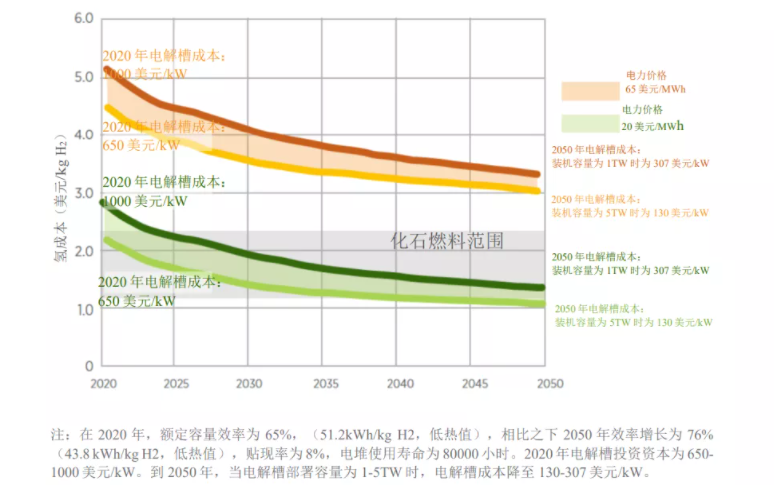

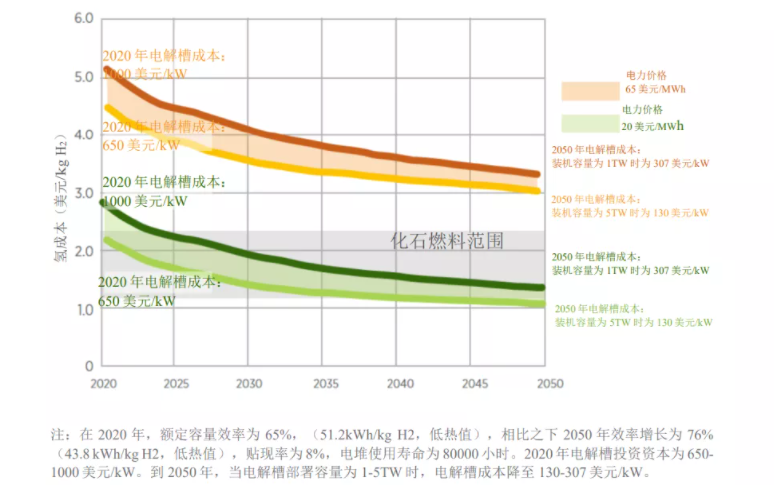

Although there is a downward trend in the cost of hydrogen production, which is largely due to the reduction in the cost of renewable energy power generation, green hydrogen is still 2-3 more expensive than blue hydrogen (produced using fossil fuel carbon capture and storage technology). More than 2 times, the cost of hydrogen production needs to be further reduced.

2. Electrolytic cell cost

Lower power generation costs alone are not enough to produce competitive green hydrogen, and there is a need to reduce the cost of electrolyzer facilities. Electrolyzer facilities are the second largest cost element for green hydrogen production and include:

■Electrolytic cell design and construction:Increasing module capacity and promoting innovation by increasing stack production have a significant impact on cell cost. The expansion of the electrolysis plant from 1MW (currently typical capacity) to 20MW can reduce costs by more than 1/3. However, cost is not the only factor affecting the size of an electrolysis plant, as different technologies use different stack designs and vary from manufacturer to manufacturer. The optimal system design also varies depending on the application area to improve system performance such as efficiency and flexibility.

■Economies of scale:The upgrading of reactor production to automated production at large gigawatt-scale production facilities can drive a step-down in costs. At low productivity, the reactor production cost accounts for about 45% of the total cost, while at high productivity, the reactor production cost as a proportion of the total cost can be reduced to 30%. For proton exchange membrane (PEM) electrolysers, the critical point of scale is about 1000 units (1MW stack)/year, which can reduce the stack production cost by about 50%. In addition, the cost of the surrounding support is as important as the electrolyser stack, and the standardization of system components and plant design can also save costs.

■Material procurement:Rare materials are also a major obstacle to the cost reduction and scale development of electrolyzers. PEM electrolyzers are expected to achieve a capacity of about 100 GW/year by 2030, but the current production of its components iridium and platinum is only expected to support a capacity of 3 GW-7.5 GW/year. However, the world's leading alkaline cell manufacturers have begun to implement other solutions to avoid the use of these materials and have developed technologies that significantly reduce the need for the use of these materials in PEM cell production. Anion exchange membrane (AEM) electrolyser technology avoids the use of rare materials from the early stages of technical research.

■Operational efficiency and flexibility:From an economic point of view, the loss of power supply efficiency will be great when the load rate is low, which limits the flexibility of the system. The modular design of multiple stacks and power equipment units in the electrolysis plant can solve the problem of efficiency loss. The compressor may not be able to change the production speed as quickly as the stack, so it may also become a major bottleneck limiting the flexibility of the system. One solution is a holistic design of the electrolysis plant that optimizes and integrates electricity and hydrogen storage to have sufficient capacity to cope with the volatility of production. If the value of related flexibility services is recognized and the price is appropriate, green hydrogen production can provide great flexibility to the power system. Given that there is no other effective competitive alternative, hydrogen will play a key role in providing a cross-seasonal reserve of renewable energy. Although this will cause significant efficiency losses, it is an important foundation for the power system to achieve 100 percent renewable energy, because the power system will then be connected to a very high proportion of volatile energy sources such as solar and wind.

■Industrial applications:The design and operation of the electrolyzer system can be optimized for specific application scenarios. These include: large industrial user scenarios that require stable supply and low logistics costs; large off-grid power plants with access to low-cost renewable energy, but high transportation costs to deliver hydrogen to end users; and decentralized production facilities that use small units to increase flexibility to compensate for higher inputs per unit of electrolyzer capacity at lower transportation costs (or near zero on-site consumption).

■Learning rate:Several studies have shown that the potential learning rate of fuel cells and electrolysers is similar to that of solar photovoltaics, which can reach 16% to 21%. This is significantly lower than the 36% learning rate achieved by solar PV over the past decade (IRENA,2020a). With this learning rate and the deployment path set to achieve the 1.5°C climate target, electrolyzer costs are expected to be reduced by more than 40% by 2030.

3. Electrolytic cell efficiency:

Under the working pressure of 3MPa, the efficiency of alkaline tank is between 50% and 78%.

Under 7MPa working pressure: PEM efficiency is 50% ~ 83%.

4. Equipment operation rate (full load hours)

Depending on the number of hours worked by renewable energy. For example, China's solar energy is about 5 hours a day; the annual average of onshore wind power is more than 1500 to 2500 hours; offshore wind power is more than 3000 hours.

5. Life of electrolyzer

The actual engineering of alkaline electrolyzers can currently be more than 15 years; PEM is still unknown (the theoretical life is not bad).

6. WACC (weighted average cost of capital)

Refers to the total cost of capital calculated by the weighted average of the cost of capital of various long-term funds, based on the proportion of various capital in the total capital of the enterprise. The weighted average cost of capital can be used to determine the required rate of return for projects with average venture capital.

How 2. can reduce the cost of electrolyzers

The government level can support electrolyzer innovation by issuing the following clear long-term support policy signals:

1. Promote investment in the production, transportation and use of green hydrogen, and encourage investment in various areas that will help to enhance the competitiveness of this low-carbon energy carrier; including reducing technical costs, improving equipment performance, increasing material supply, establishing business models and trading according to common standards and certification systems.

2. Establish regulations and create markets to support investment in innovation and scale up green hydrogen production. These include the establishment of equipment manufacturing or deployment targets, tax incentives, mandatory quotas for sectors that are difficult to decarbonize, and other risk reduction mechanisms, while implementing new business models to safeguard the expected returns on large-scale private sector investments.

3. Support research, development and demonstration (RD & D) projects to achieve the following goals: reduce the use of iridium and platinum in PEM cell production; promote the conversion of all alkaline cells to platinum-free and cobalt-free equipment; and overall mandatory reduction in the use of rare materials as a prerequisite for production scale.

4. Promote synergy and unity of objectives across the entire value chain of hydrogen energy, across regions, across industries and among stakeholders.