Analysis of Parameter and Operating Load of Hydrogen Production Equipment by Water Electrolysis

Release time:

Apr 27,2022

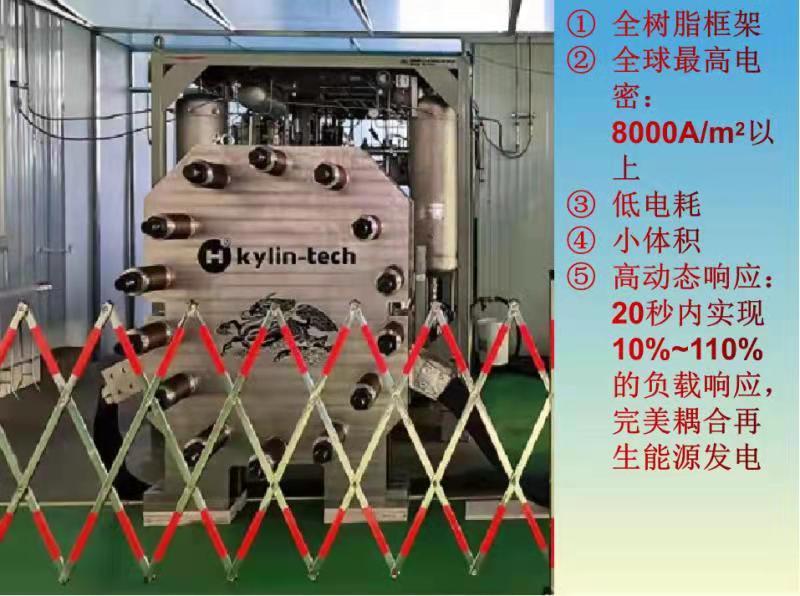

In the conventional process of electrolysis water for hydrogen production, the voltage required by the electrolysis water hydrogen production equipment is stable and rated. Typically, the alternating current from the power grid is rectified and inverted to supply direct current to the electrolysis water hydrogen production equipment. However, this power supply form is difficult to meet the requirements of wind and solar power, so the current characteristics of electrolysis water equipment cannot be effectively combined with the characteristics of wind and solar power. To align the characteristics of electrolysis water equipment with wind and solar power, it is necessary to make corresponding improvements to the conventional electrolysis equipment to meet its electrolysis needs.

Currently, the alkaline electrolyzer technology that has achieved industrial application is relatively mature. The normal operation of the electrolyzer is mainly determined by the following parameters: the theoretical operating current density is generally in the range of 1500-4000 A/m2, corresponding to a cell voltage of around 2.0V. Its electrolysis efficiency is relatively ideal, but during practical operation, when the current density exceeds 100A/m2, the overall electrolysis current efficiency becomes very stable, reaching over 95%. This shows that to ensure the normal operation of the electrolyzer, it is only necessary to achieve a current density of over 10% of the rated current density, which is easily satisfied by non-grid-connected wind and solar power.

In addition, the electrolyzer of the electrolysis water hydrogen production equipment should ensure that the gas production volume is above 10% of the rated gas production volume. Only in this way can it meet the control requirements (mainly involving gas pressure and liquid level control during the electrolysis process), ensuring the stable operation of the entire electrolysis water equipment and producing hydrogen that meets quality requirements.

Key words:

Related News