Kylin Technology: Breaking the "impossible Triangle" performance and "Innovation Ceiling" for Alkaline Electrolyzer

Release time:

Jan 28,2023

The hottest-discussed topic in hydrogen field in 2022 is the electrolyzer manufacturing enterprise. In order to utilize green electricity and green hydrogen under the global carbon neutral target, all kinds of energy enterprises are "running" into the market. In 2023, the electrolyzer stacks are expected to be produced in large-scale, and the electrolyzer stack manufacturing enterprises with promising technologies will be appreciated by investors.

Kylin Technology, a formidable yet understated contender, has emerged as a trailblazer in the industry. In 2021, the company pioneered the world's first "ALK cost PEM performance" all-off-grid, large-scale alkaline electrolyzer stack for mass production, boasting "low cost, high capacity, and fast response." This innovation shattered the conventional "impossible triangle" of electrolyzer stacks, paving the way for new innovations in alkaline electrolyzer stack technology. With this groundbreaking product, Kylin Technology has vaulted into the forefront of global large cubic electrolyzer manufacturers, solidifying its position as a global leader in hydrogen production equipment and a premier provider of "green electricity and green hydrogen" solutions worldwide.

Kylin Technology, a veteran in the hydrogen production equipment industry, was founded in 2008. Boasting a founding team with two decades of experience, the company possesses profound insight into the evolving trends and a global perspective of the hydrogen production equipment sector. Maintaining a forward-thinking and systematic approach to technology, Kylin Technology's product development philosophy centers on addressing industry challenges and striving for the creation of multi-scenario, cost-effective, and universally applicable products.

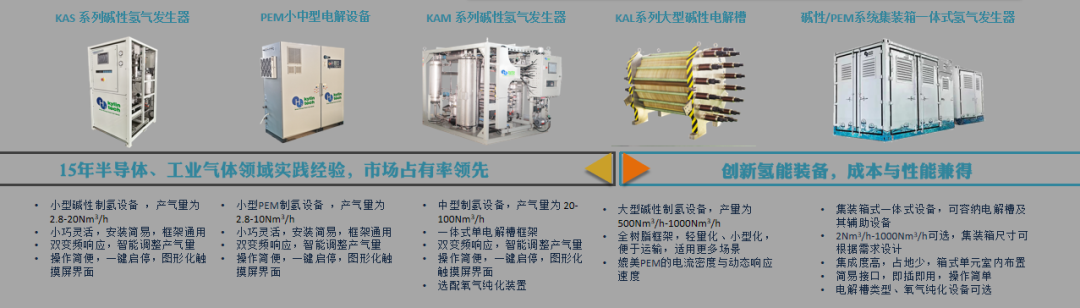

In 2022, the annual production capacity of Kylin Technology electrolyzer stack will reach more than 500MW. At present, the company has formed a full range of 2-1000Nm 3/h alkaline hydrogen production research and development and production capacity, with 1-1000Nm 3/h PEM hydrogen production equipment design and production capacity.

Photos provided by Kylin Technology and edited by Hydrogen Cloud Chain

Photos provided by Kylin Technology and edited by Hydrogen Cloud Chain

From the perspective of technical routes, the innovative thinking of Kylin Technology is similar to ThyssenKrupp - through improvements in materials, processes, and product structures, they aim to break through the "ceiling" of traditional alkaline electrolyzers and lead the industry.

From the perspective of product verification, ThyssenKrupp's products have undergone product verification in steel mills and are suitable for large-scale hydrogen usage scenarios such as chemical plants and steel mills. The current order volume exceeds 10 billion, with a valuation of nearly 30 billion. On the other hand, Kylin Technology's products have achieved technological and product verification in domestic "green power coupling" scenarios, meeting the requirements for large-scale promotion of "green power for green hydrogen production." In terms of product performance, price, and production delivery capabilities, Kylin Technology's electrolyzers are currently more advanced a step ahead ThyssenKrupp.

From the perspective of technological innovation, Kylin Technology's large-scale electrolyzers boast the globally unique advantage of high-performance products: Alkaline price + PEM performance. In other words, Kylin Technology's products have achieved the characteristics of "alkaline price and PEM performance", reaching the global leading level in four aspects: current density, power consumption, dynamic response, and compactness/lightweight.

The leading advantages of the four core indicators of Kylin Technology's large-scale electrolyzers are as follows:

1. The current density is 2-3 times higher than the industry average level. The rated working current density of Kylin's electrolyzer has reached over 8000A/m2, approaching the level of PEM electrolyzers at 10000A/m2, and is 3 times higher than that of conventional alkaline electrolyzers.

2. The power consumption has reached an internationally advanced level. Under 100% load, the power consumption of Kylin's electrolyzer is 4.6kwh/Nm3, basically on the same level as internationally leading enterprises (such as NEL), surpassing the common standard of 4.8-5.0kwh/Nm3.

3. With a wide load range and a leading dynamic response, Kylin's electrolyzer has a significant lead in dynamic response and adjustment range compared to the industry. It can complete a 10% to 110% hot standby dynamic response within 20 seconds, which is only one-tenth of the time taken by conventional electrolyzers, fully meeting the requirements of renewable energy hydrogen production.

4. Miniaturization and lightweight design. Currently, conventional electrolyzer equipment with a capacity of 1000Nm3/h on the market weighs over 50 tons and has a bulky design, which is not conducive to installation and transportation. However, the volume and weight of Kylin's electrolyzer are only 1/4 to 1/5 of conventional electrolyzers, making it suitable for more application scenarios with vast market potential.

Images: Kylin Technology

HydrogenCloudChain's view is that the large-scale electrolysis of hydrogen has driven the first wave of technological and product changes in the current round of electrolyzer development, characterized by large-scale hydrogen production per single electrolyzer, giving birth to a batch of new electrolyzer products. Globally, the green hydrogen equipment industry is still in the verification stage of new technologies and products, and existing products cannot fully meet the needs of new scenarios such as green hydrogen. For example, 1) conventional alkaline routes: low cost, high capacity, but difficult to couple with green electricity; 2) conventional PEM routes: able to couple with green electricity but high cost and low capacity. It is clear that exploring "usable and user-friendly" products is the direction of global enterprises' innovation at this stage.

HydrogenCloudChain analysis shows that as large-scale renewable energy hydrogen production moves from concept to practical application, scenarios such as on-site hydrogen production and industrial electrolytic hydrogen production are emerging. In addition to high power and low cost, the market has put forward a series of new requirements for the development of electrolyzer technology: off-grid, small size, high stability, and easy maintenance.

Overall, Kylin Technology's large-scale electrolyzer products are unique, with outstanding product advantages in fully off-grid coupling with renewable energy power generation. Kylin Technology has taken the lead in globally launching a mass-produced alkaline electrolyzer product with "ALK cost + PEM performance" that is fully off-grid and large-scale, featuring "off-grid, small size, high stability, and easy maintenance", leading the global electrolyzer product innovation trend. With its "low cost, high capacity, and fast response," this product has broken through the current "impossible triangle" of electrolyzers and opened up the "ceiling" of alkaline electrolyzer innovation, becoming a leader in the global hydrogen production equipment field and a dark horse in the hydrogen production equipment industry, with promising development prospects!

Key words:

Related News