8000A Current Density, 20 seconds response time to full load! A number of Stated Owned Energy Enterprises, International giants witnessed Kylin's 6 unique Technologies

Release time:

Apr 26,2023

Which Technology Represents the Future: The New Generation of Innovative Alkaline Electrolyzers or PEM? Which Better Meets Market Demand? To address issues such as insufficient market awareness, Kylin Technology, a representative of large-scale innovative alkaline electrolyzer manufacturers, held the first technology and product showcase week from April 17th to April 23rd, 2023, attracting over 20 well-known domestic and international companies and institutions. During the event, Kylin's 500 Nm³/h innovative alkaline electrolyzer demonstrated its hydrogen production scale, current density, power consumption, and other characteristics in real-time. Through demonstrations such as "cold startup in 20 minutes," "increaseing to full load in 20 seconds and decreasing to lowest load in 1 second," and "stable hydrogen production at 10% load," the company showcased its six major characteristics: high current density, fast response, wide load range, quick startup, high safety, and low power consumption.

As global electrolysis equipment is in the new technology validation stage, issues such as insufficient product performance and high equipment vacancy rates have emerged. Among them, the "green hydrogen impossible triangle" of "power-response-cost" is the most significant challenge and a crucial link in achieving green hydrogen parity. Companies represented by Kylin Technology in China and ThyssenKrupp abroad have made breakthroughs, achieving "alkaline price with PEM performance." However, due to the lack of demonstration projects and inadequate promotion, the market has insufficient awareness of innovative technologies, leading to suspicisions. HydrogenCloudChain believes that the Kylin Technology showcase week used real products to speak, changing the industry's perception of electrolyzer innovation directions, enhancing confidence in the green hydrogen market, and contributing to refining the market's views on the development of electrolyzer technology. This was a highly effective event that achieved multiple objectives.

The Kylin Technology showcase week demonstrated that Kylin's large-scale innovative alkaline electrolyzer performs comparably to PEM, and its high cost-effectiveness, combining "ALK cost with PEM performance," better meets current market demand.

Through the Kylin new technology and product showcase week, Kylin Technology had in-depth exchanges with over 20 global well-known companies and professional institutions, enhancing the industry's awareness of its innovative alkaline electrolyzers. Together, they explored the development trends of technical routes and increased confidence in the green hydrogen industry. HydrogenCloudChain believes that companies that take the lead in breaking through the "green hydrogen impossible triangle" are likely to gain a competitive advantage.

HydrogenCloudChain hopes that more innovative companies will enhance society's awareness of the green hydrogen market and innovative products through various means, accelerating the development of the green hydrogen market.

1. Seeing Is Believing! Over 20 Companies Visit Kylin Technology's Innovative Electrolyzers Onsite

Kylin Technology's innovative products have garnered significant attention in the industry. However, due to insufficient market awareness of innovative products, the actual situation of Kylin Technology's products is not widely known.

To gain a deeper understanding of Kylin Technology's innovative products, explore green hydrogen solutions, and investigate the development direction of electrolytic hydrogen production technology, over 20 renowned domestic and international companies participated in Kylin Technology's showcase week. These included global industrial giants, leading energy central enterprises, and renowned investment institutions. A partial list of participating companies is shown in Table 1.

Table1 List of partially participating companies

No. | Enterprise | Remarks |

1 | CGNPC |

|

2 | Waaree Energies Limited | India |

3 | Ningbo Cuiying Chemical |

|

4 | COOOC Engineering |

|

5 | Shandong Energy |

|

6 | FUEL CELL ENERGY | United States |

7 | ATHENA SERVICE AND TECHNICAL COMPANYLIMITED | Vietnam |

8 | Foyan hydrogen energy |

|

9 | Huadian Group |

|

Explanation: Only the companies willing to disclose their information are displayed here.

Source: Kylin Technology

Figure 1: A visiting delegation from an international industrial giant with Wang Zhanyang, Chairman of Kylin Technology

Source: Kylin Technology

2. Six Unique Features of Kylin Technology's Innovative Electrolyzers

During this showcase week, Kylin Technology demonstrated six unique features of its innovative large-scale alkaline electrolyzers to the guests through live operations.

Unique Feature 1: Ultra-high Current Density of 8000A/m2, Comparable to PEM Electrolyzers

The relatively low current density of conventional alkaline electrolyzers results in their bulky size and excessive weight, limiting their application scenarios and making it difficult to achieve large-scale skid-mounted usage.

As shown in Figure 2, Kylin Technology's ALK500 electrolyzer can achieve a maximum current density of up to 8000A/m2 and can operate stably at a current density close to 8000A/m2, basically reaching the current density level of PEM electrolyzers. This is 2-3 times higher than that of conventional large-scale alkaline electrolyzers.

Figure 2: Participating companies witnessed the 8000A/m2 current density.

Source: Kylin Technology

As seen in Figure 3, the 500 Nm³/h electrolyzer is compact and space-efficient. It is understood that Kylin Technology is currently developing a skid-mounted hydrogen production equipment with a capacity of up to 1000 Nm³/h. This will be the world's first large-scale skid-mounted alkaline hydrogen production equipment.

Figure 3: Visitors with Kylin Technology's 500 Nm³/h electrolyzer equipment.

Source: Kylin Technology

- Unique Feature 2: High-speed Load Change Capability of 20S Loading and 1S Unloading

The rapid load change capability of electrolysis equipment is crucial for "green electricity to green hydrogen" production. Currently, conventional alkaline electrolyzers do not possess rapid frequency conversion capabilities, requiring connection to the power grid or supporting energy storage equipment to match green electricity.

As shown in Video 1, Kylin Technology's KAL500, under a hot standby state with an alkali liquor temperature of 80°C, can rapidly complete a power change from 0% to 100% in 17 seconds and also achieve a 1-second unloading from 100% to 0%. Simultaneously, the power consumption also adjusts rapidly, remaining largely consistent compared to steady-state conditions.

Video 1: Demonstration of Kylin Technology's KAL500 Quick change in load

(Video)

Source: Kylin Technology

3. Unique Feature 3: Minimum Stable Load Can Reach Below 10%

At this stage, the operational lower limit of most alkaline electrolyzers is between 30% and 50%, which is not conducive to matching renewable energy scenarios with large fluctuation ranges.

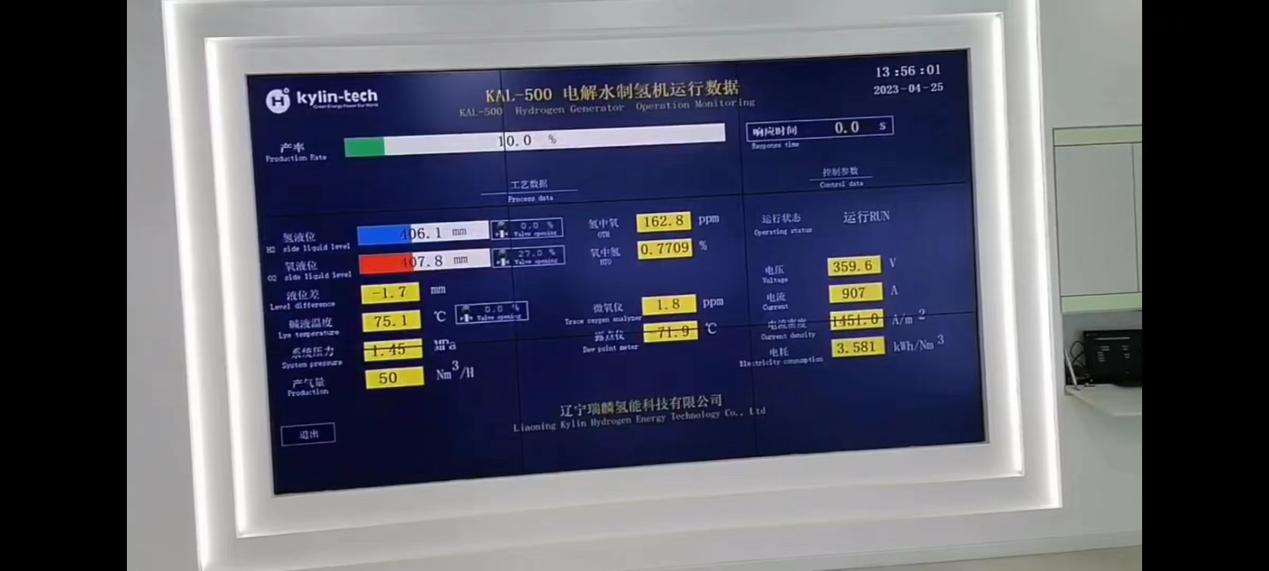

As shown in Figure 4, Kylin Technology's KAL500 can operate stably for a long time even under a load of less than 10% of its rated power.

Figure 4: KAL500 Demonstration of 10% Low-load Operating Conditions

Source: Kylin Technology

4. Unique Feature 4: High Safety with Ultra-low Hydrogen Content in Oxygen Across the Full Power Range

Due to the pressure difference between the hydrogen and oxygen production sides under low-load conditions, hydrogen can penetrate the diaphragm and mix with oxygen, posing a safety risk. Therefore, the high power load lower limit of alkaline electrolyzers is primarily attributed to the hydrogen content in oxygen.

Under low-load and rapid load change conditions, Kylin Technology's AKL500 consistently maintains the hydrogen content in oxygen below 1%, ensuring high safety for the electrolyzer under various operating conditions.

5. Unique Feature 5: Cold Start in 20 Minutes

In green hydrogen production scenarios, conventional alkaline electrolyzers often require 1-2 hours for cold startup, and the daily effective working time of photovoltaic systems is only 6-8 hours, resulting in significant waste.

Kylin Technology's KAL500 can complete a cold start in 20 minutes, significantly reducing waste during the electrolyzer's startup.

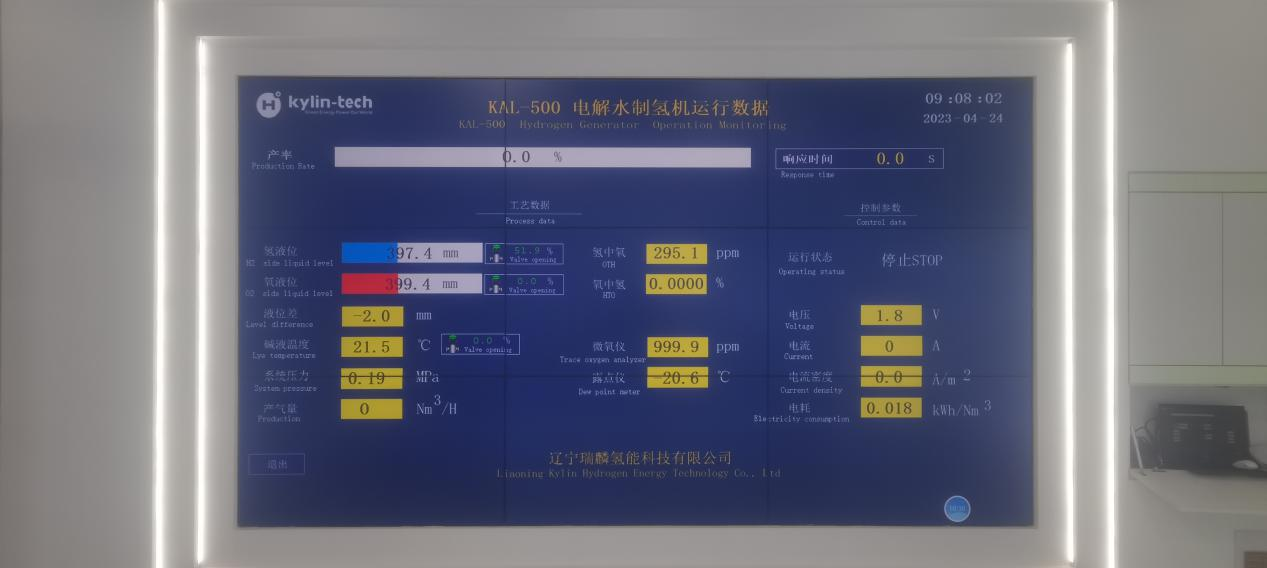

As shown in Figure 5, the startup occurred at 9:08, and by 9:18, the alkali liquor temperature had risen from 21°C to 31°C, the yield had increased to 30%, and the hydrogen production rate reached 150 Nm³/h.

Figure 5: KAL500 Cold Start Demonstration

Source: Kylin Technology

6. Unique Feature 6: Achieving Both High Current Density and Low Power Consumption

Conventional alkaline electrolyzers often exhibit a pattern of "low current density-low power consumption, high current density-higher power consumption." At full load, the power consumption increases significantly, making it difficult to achieve both high hydrogen production and low power consumption.

Kylin Technology's products have broken the conventional experience curve slope of "high current density-higher power consumption" and achieved "high current density-low power consumption." At 4000A/cm², the power consumption is lower than 4.2kWh/Nm³, and even at the rated current density of 8000A/cm², the power consumption remains below 4.6kWh/Nm³.

High Praises! Enterprises Highly Evaluate Kylin Technology's Innovative Alkaline Electrolyzer

The six unique features of Kylin Technology's KAL500 amazed the guests.

A guest from an international industrial giant expressed: "The response speed of Kylin Technology's equipment is extremely fast, reaching the same level as PEM electrolyzers. The hydrogen content in oxygen is very low, whether under low load or during rapid load changes, without triggering safety limits. It's truly amazing."

A guest from Vietnam commented: "From the equipment's size, appearance, to the materials used, Kylin Technology's products are indeed different from traditional alkaline electrolyzers. We are very surprised by such a compact device."

Figure 6: Photo of Vietnamese Customers

Source: Kylin Technology

Domestic customers have also expressed amazement at the level of power consumption: "With such high power density, the power consumption is still maintained at a relatively low level, which indeed breaks through the characteristics of ordinary alkaline electrolyzers."

Figure 7 Domestic energy companies visiting the site

After the exhibition week, Mr. Wang Zhanyang, the Chairman of the company, expressed his belief that Kylin Technology's products would soon bloom worldwide. With the strong support from domestic enterprises and industry experts, Kylin Technology is confident that it will meet everyone's expectations and deliver outstanding results!

Key words:

Related News